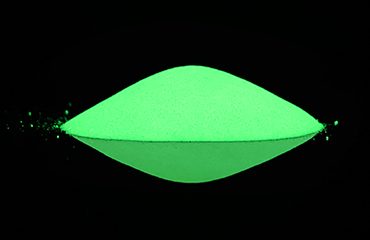

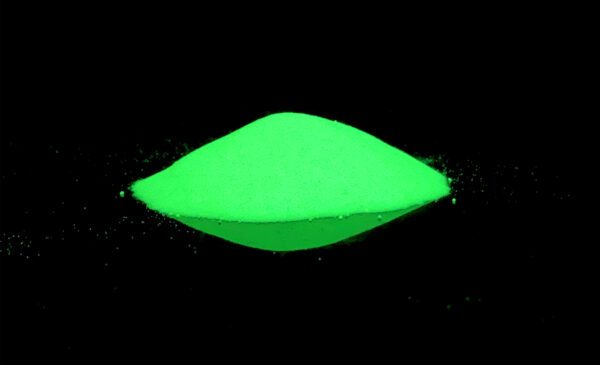

Ultra-high Brightness Glow In The Dark Pigment

Ultra-high Brightness glow in the dark pigment, as the name implies, is a series of glow in the dark pigment which can produce ultra-high brightness and longer afterglow. After fully charged of 15-20 minutes of direct sunlight for example, it can glow for 10-12 hours or even above 12 hours for specific types in an all-black room.

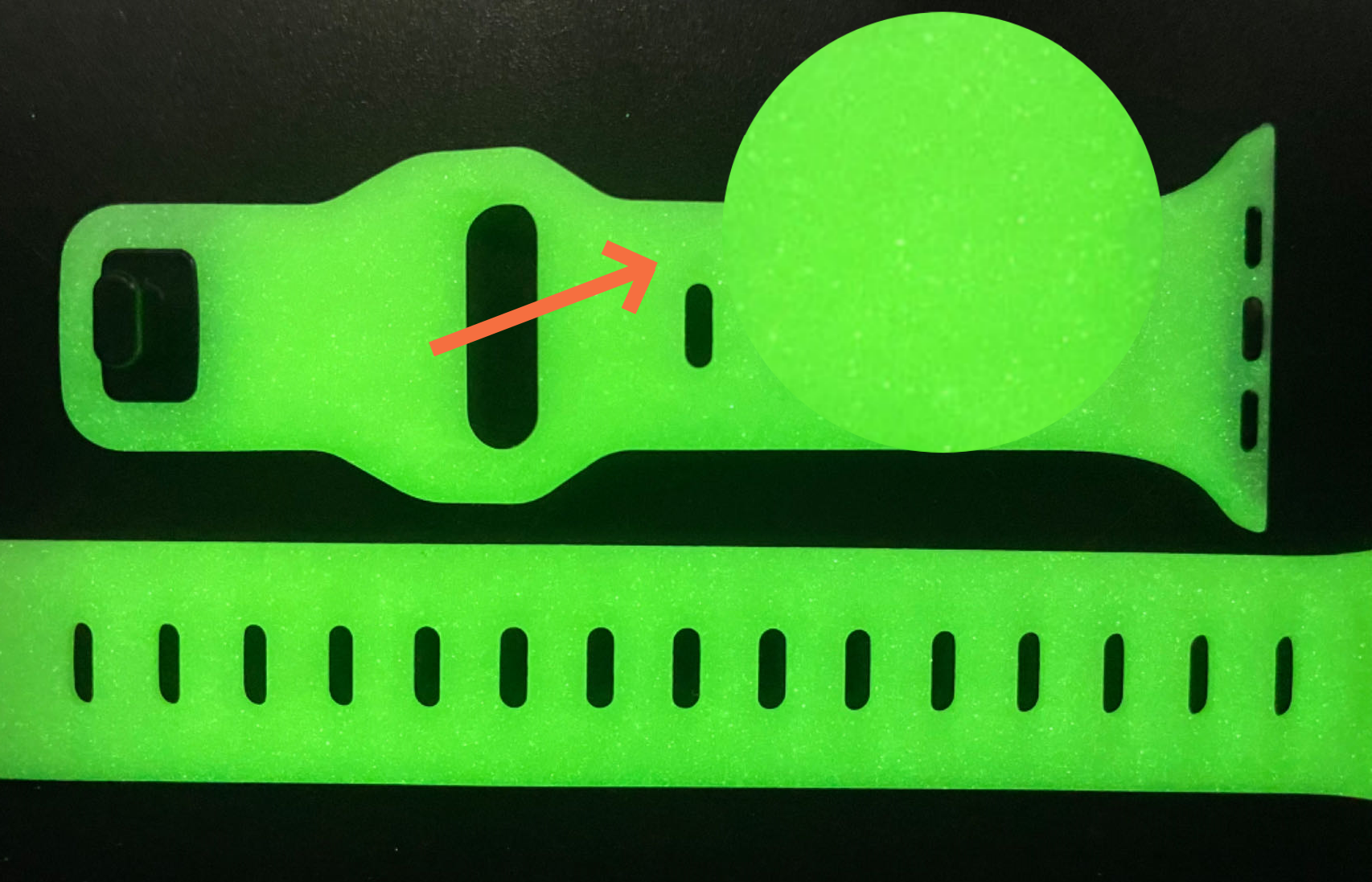

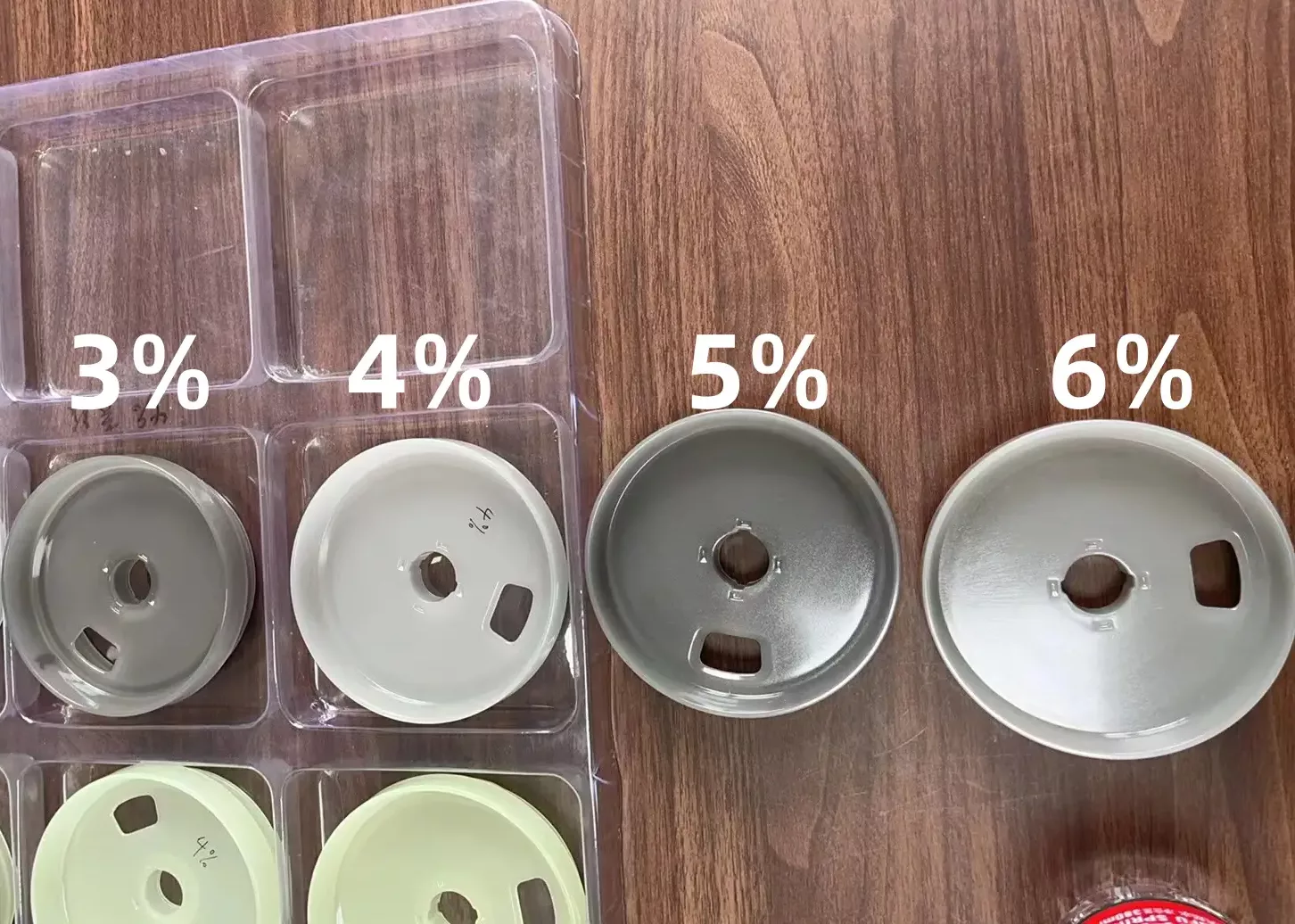

Comparing with normal brightness level, Ultra-high series is made by special formula. It is perfectly suitable for safety industry, such as escape and firefighting facility signs, and the applications which pursuing ultimate luminance. It can act as weak lighting devices in underground car parks, shopping malls, cinemas, subways, office, and warehouse when suddenly power off. It also plays a good role in outdoor projects for road markings, construction decorations and marine facilities etc.

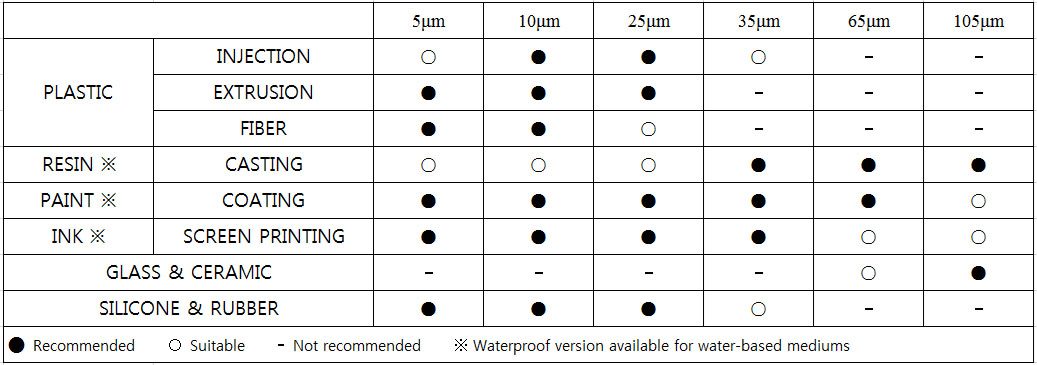

APPLICATAIONS & RECOMMENDATION

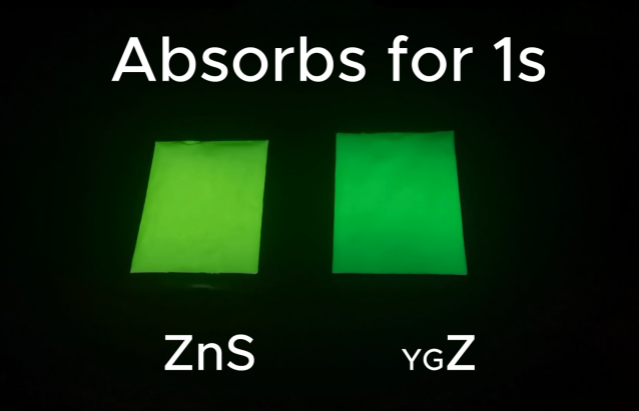

YELLOW-GREEN

BLUE-GREEN