Special Glow in The Dark Pigment For Plastic

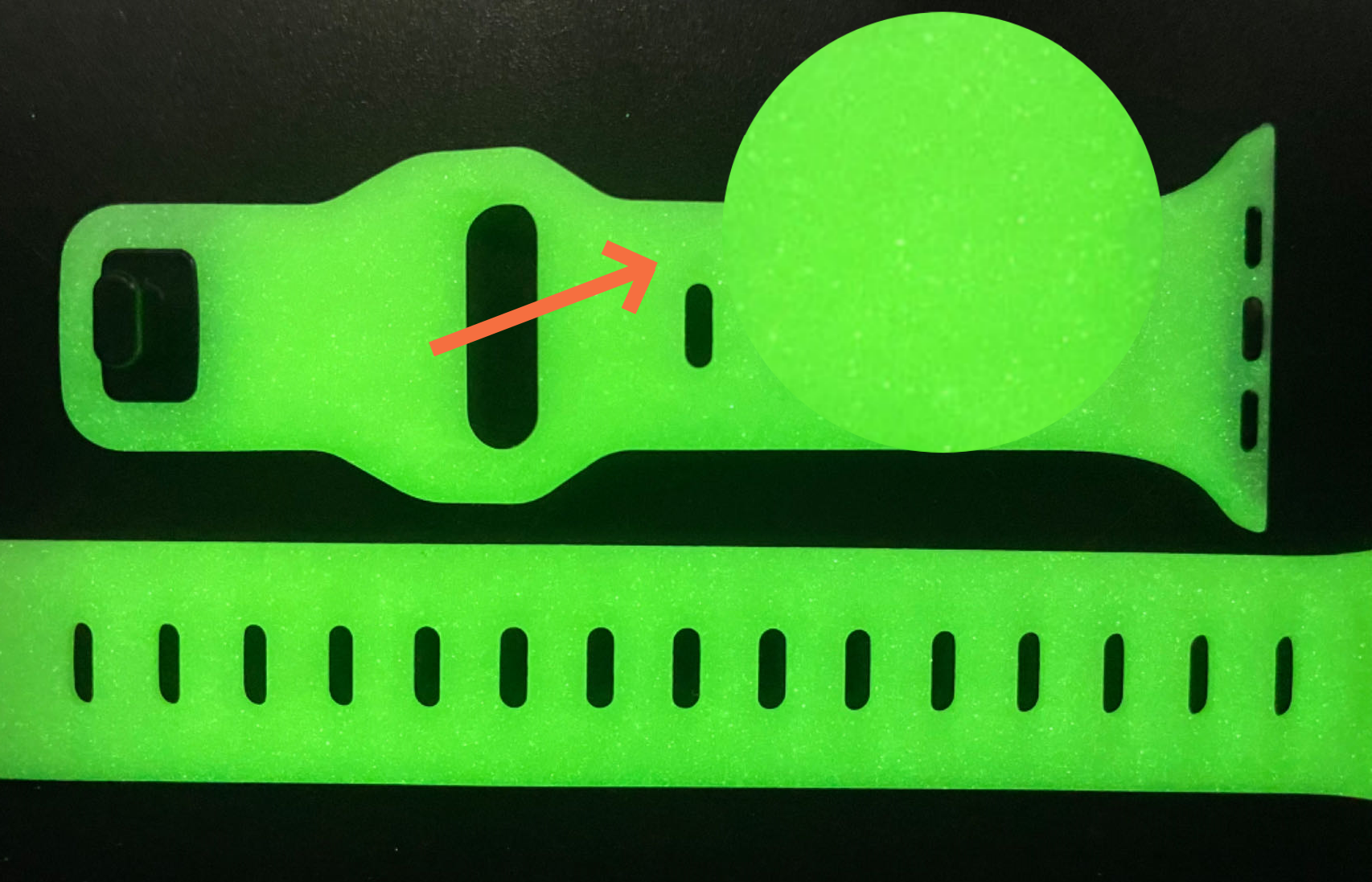

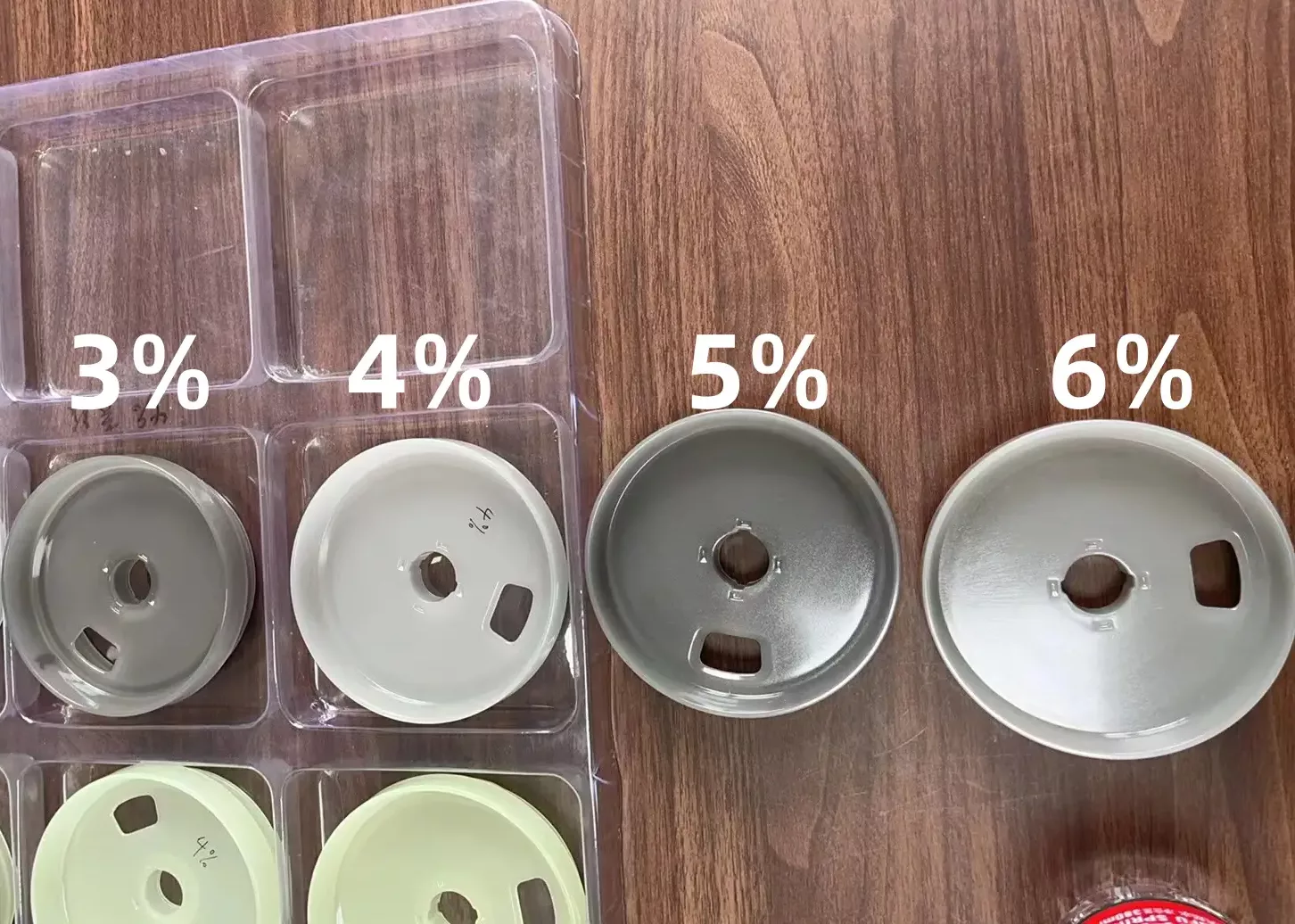

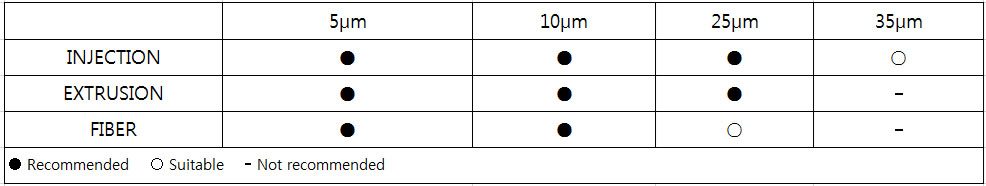

This type of pigment has a better performance on plastic products. After a special treatment, it has better dispersion and less friction during the production process. At the same time, it has an excellent UV resistance and weather resistance. It is usually used in housewares, sports goods, toys etc, and is suitable for technics as injection, extrusion, wire drawing and so on.

APPLICATAIONS & RECOMMENDATION

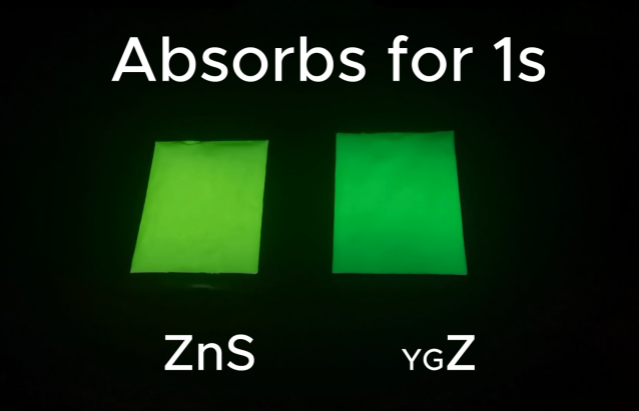

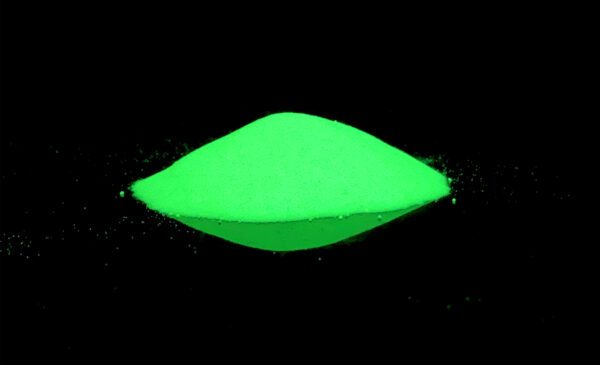

YELLOW-GREEN

BLUE-GREEN