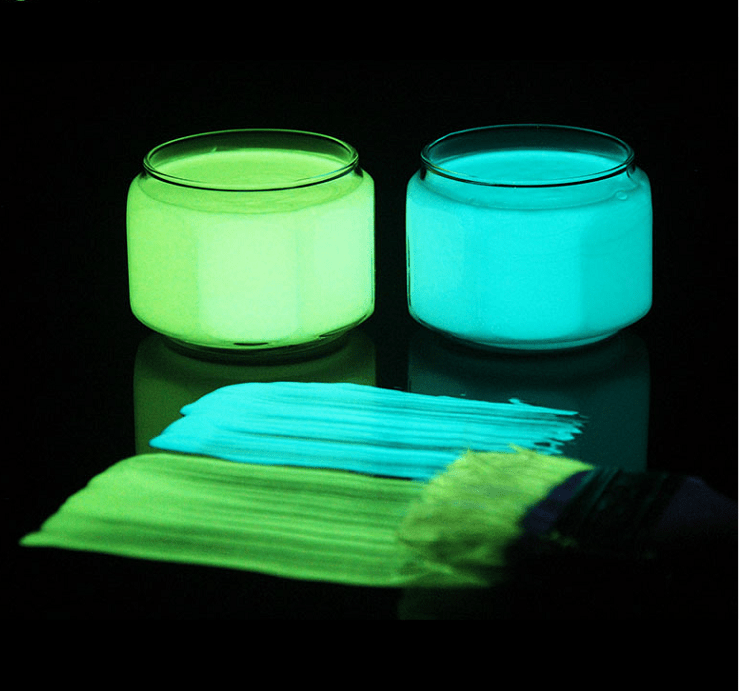

glow in the dark powder mixed with paint

Glow in the dark pigment can be activated by all visible light or ultraviolet light ,then emit light in the dark. It’s non-toxic, non-radiation, eco-friendly. It can be mixed with paint for making glow in the dark paint which can be applied for building decoration or art painting.

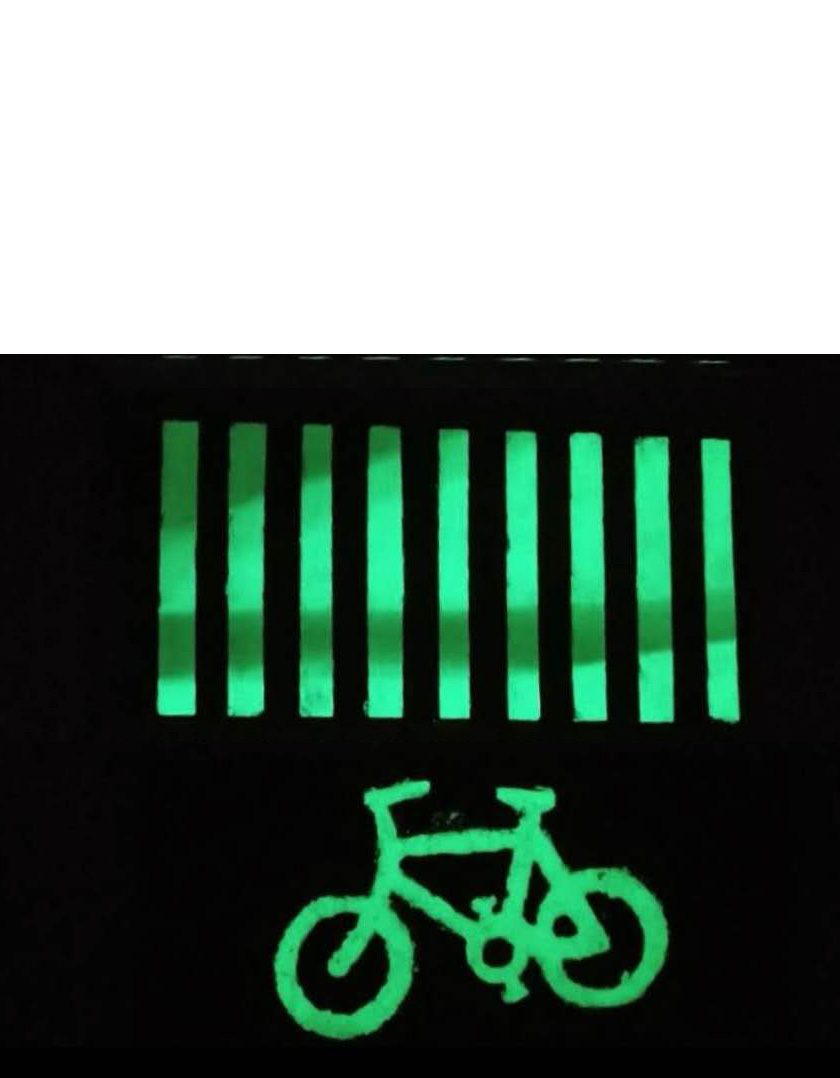

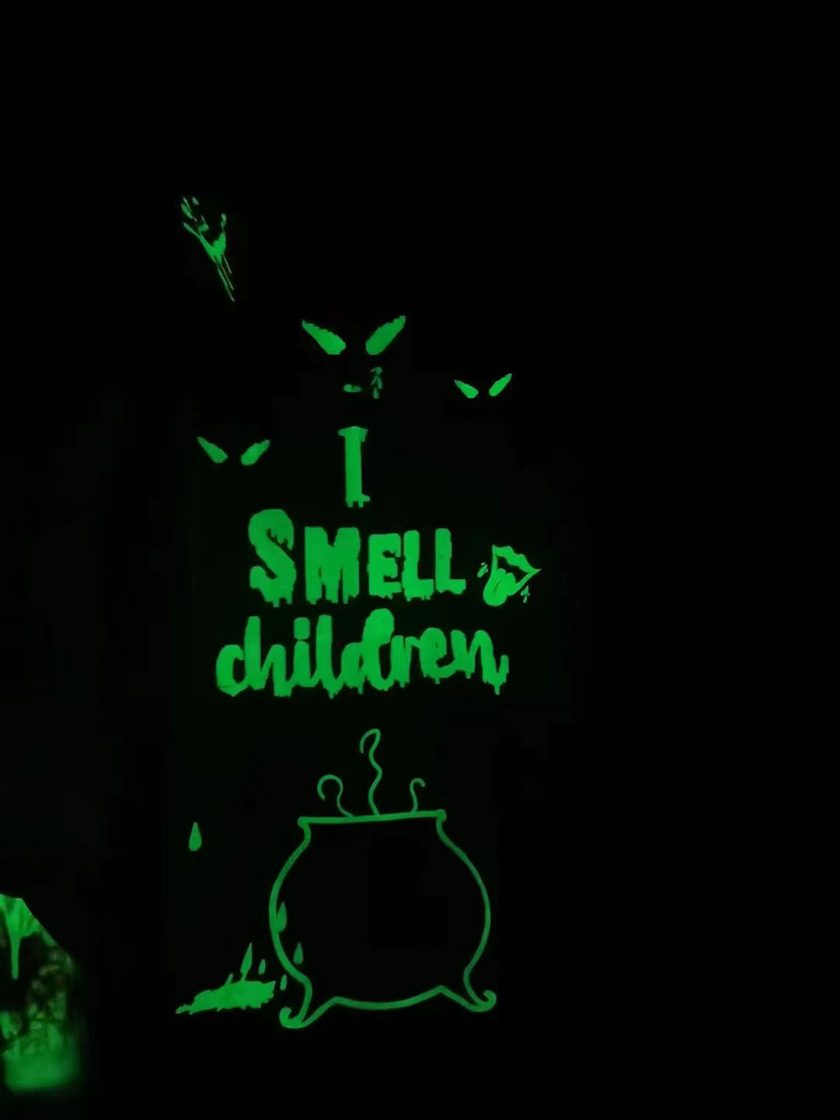

Glow in the dark paint used on wall and road marking ,can not only improve the visibility of signs itself and the surrounding environment, but also remind passerby or drivers of key instructions and upcoming curves. yellow green color is mainly used due to it’s brightest. We can also do art painting on paper or canvas, it can achieve innovative and excellent artistic performance at night.

Many colors can be chosen.

When you mix the glow in the dark pigment with paint, you need to choose transparent colorless PH 6-8 paint. If the paint is water-based, water-proof pigment need to be used. Glow in the dark paint can be brushed,rolled and sprayed.