Ultra-fine Glow In The Dark Pigment

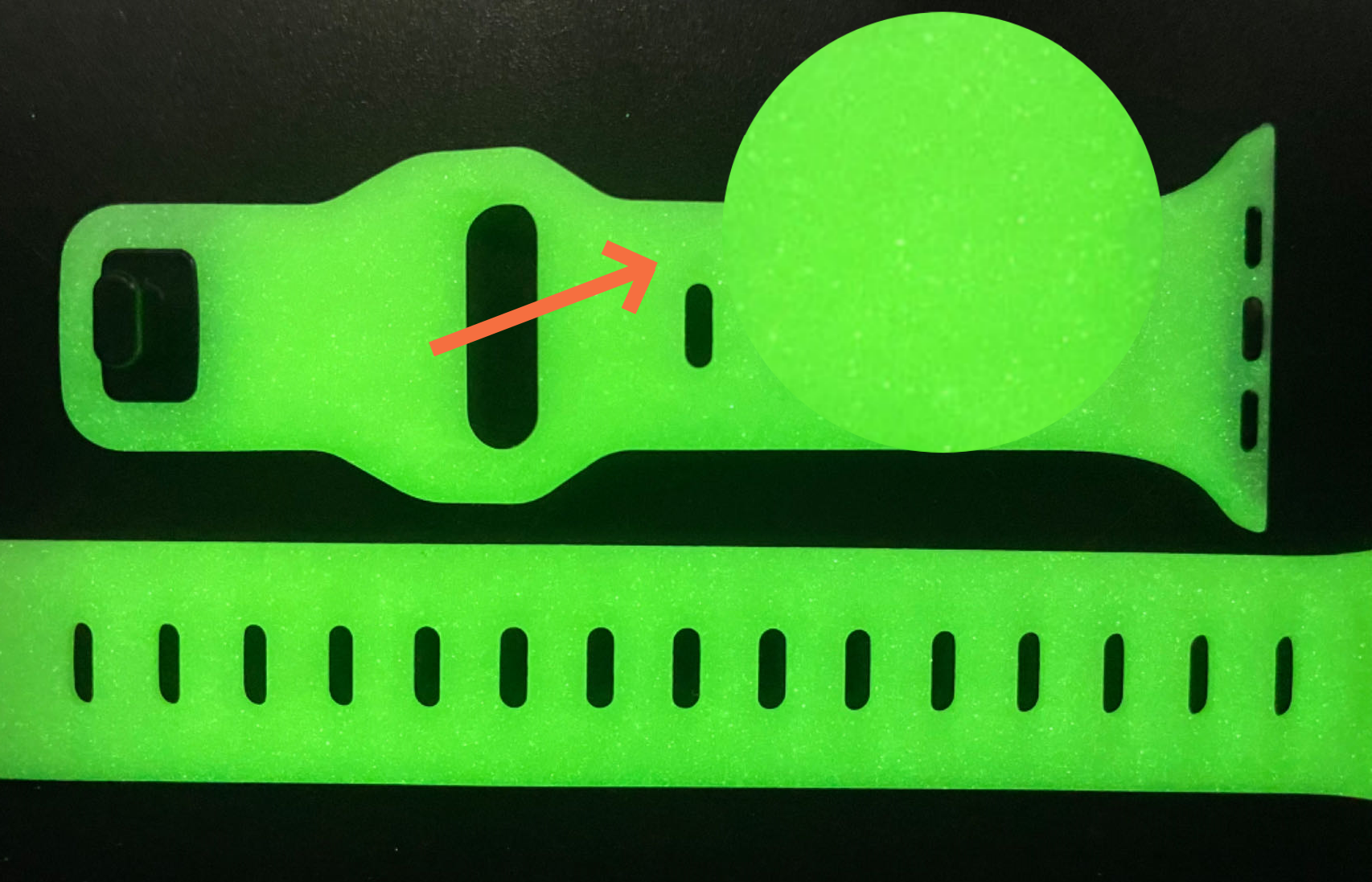

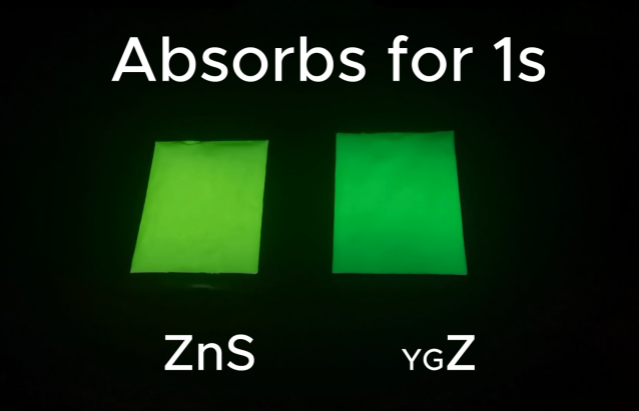

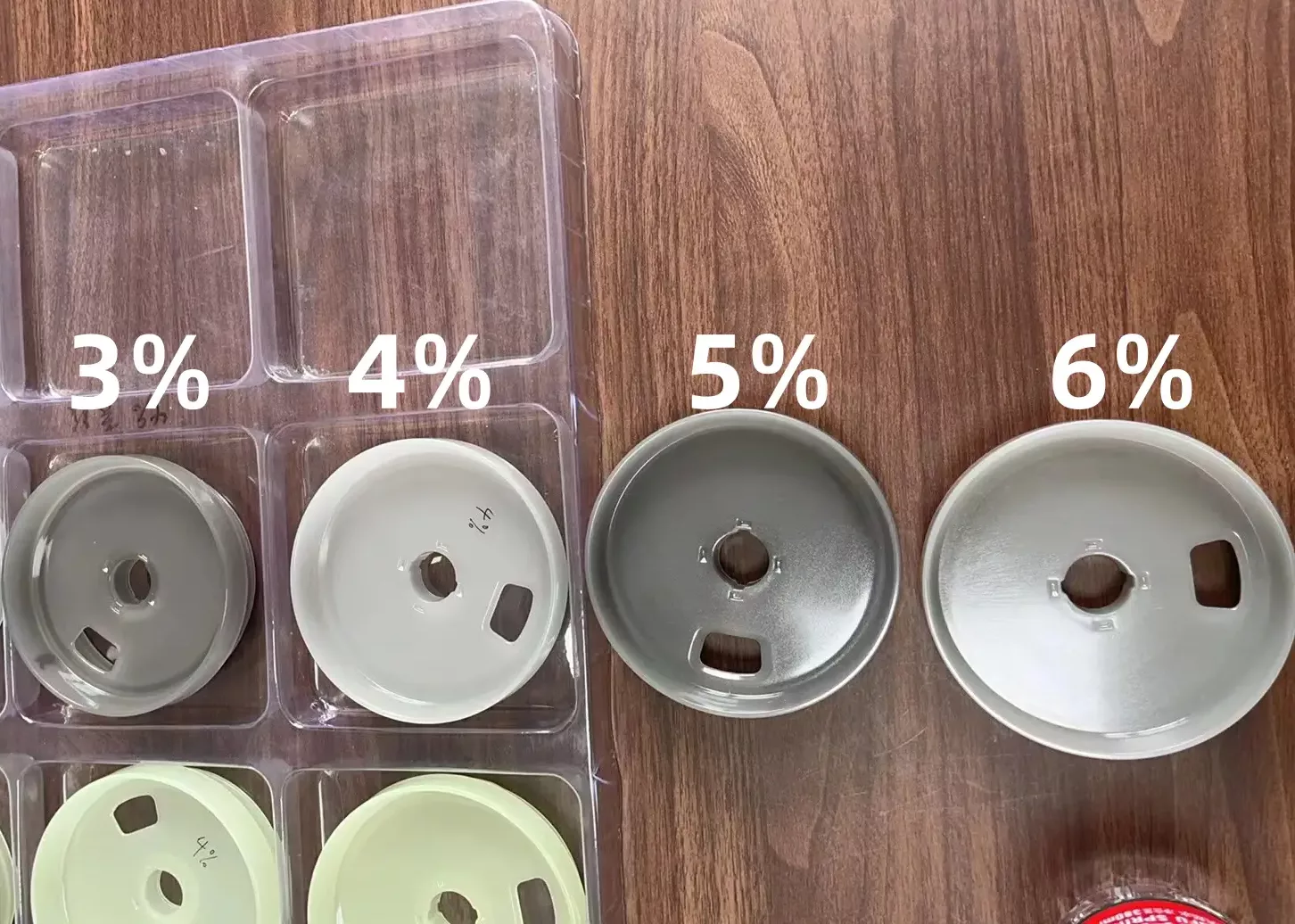

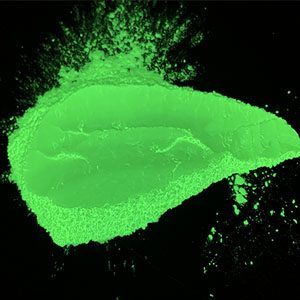

Ultrafine glow in the dark pigment, made by a special process, has tiny particles with average size about 5-12 microns, which is finer than regular glow-in-the-dark pigment. It’s widely used in the printing industry such as gravure, flexographic, and offset printing after mixing with transparent and neutral ink, giving printed materials a unique glow. This fine powder also works well in fibers and thin-layer coatings, improving visibility at night and meeting the need for small particles. It comes in colors like yellow-green and blue-green, which create eye-catching effects in various applications.

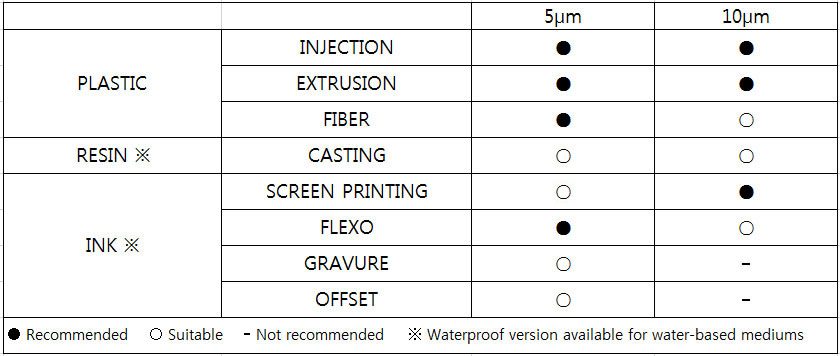

APPLICATAIONS & RECOMMENDATION

YELLOW-GREEN