Glow-in-the-dark powder was initially used in the safety field, mainly to deal with sudden power outages. Its self-luminous properties can indicate escape routes or serve as reminders in the dark. From the signage on airplanes and subways to safety markings in office buildings or underground garages, and safety gear worn by workers in enclosed environments such as mines, all rely on the characteristics of glow-in-the-dark powder for development of important safety equipment. Such applications require the powder to have a long afterglow time, typically about 10-12 hours, without the need to focus on the speed of light absorption. The safety signs can theoretically be charged continuously, waiting for a sudden blackout to start glowing.

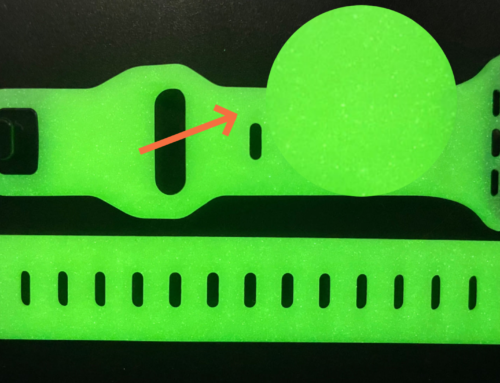

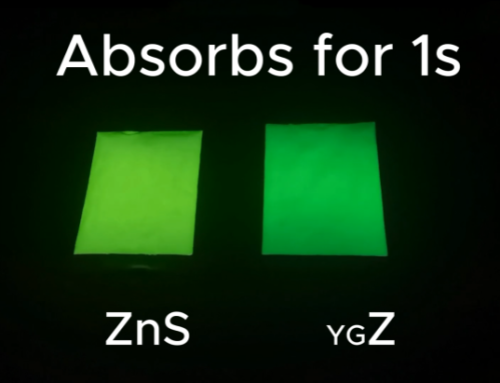

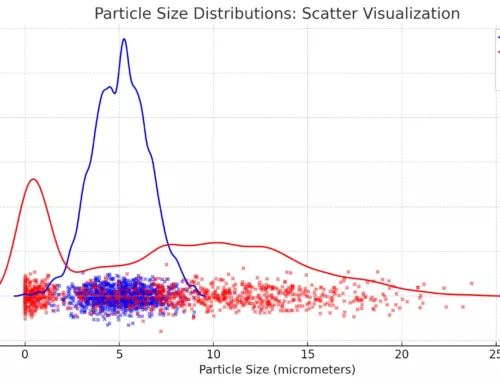

As the application of glow-in-the-dark powder has expanded, more and more consumer products have begun to favor this element. In this field, glow-in-the-dark products are used more for indoor low lighting and short irradiation times, exposing a shortcoming of traditional glow-in-the-dark powders: weak initial brightness. However, the characteristics of glow-in-the-dark powder itself determine that a high initial brightness will result in a shorter afterglow time. After about half a year of formula adjustments and hundreds of experiments, we have finally found a balance between initial brightness and afterglow time. We have launched a new product, YGH Series, which has a high initial brightness, fast light absorption, and can also maintain a long afterglow time.

After providing the new product to customers in industries such as textiles, plastics, and paints for trial, they have given positive feedback. Because in the consumer product field, users generally do not need a long time of afterglow, but they do want the product to be quickly usable without having to charge for tens of minutes before use.

Listening to customer needs and developing products to better meet those needs has always been Glowup’s focus. We will continue to strive for this.

Leave A Comment