The structure of glow-in-the-dark powder means that larger particles store more light energy and are therefore brighter. However, in practical applications, large particles cannot be chosen solely for higher brightness, as many production processes or product characteristics impose certain limitations on particle size, such as the mesh size in screen printing and the nozzle diameter in spray painting. Large particles can clog screens or nozzles, affecting production. Too small particles, on the other hand, may lead to a less noticeable glow effect. Ultra-fine particles are needed for ultra-thin coatings; otherwise, too large particles can cause uneven surfaces or make the product brittle and crack, affecting the aesthetics, smoothness, and practicality of the product. Furthermore, the particle size of glow-in-the-dark powder can affect the dispersibility and stability during the production process when mixed with a liquid medium. For example, larger particles settle faster, causing the powder to accumulate at the bottom. If stirring is insufficient for too small particles, agglomeration can occur, leading to spotty luminescence. Therefore, the appropriate particle size is a primary factor for the smooth production of glow-in-the-dark products.

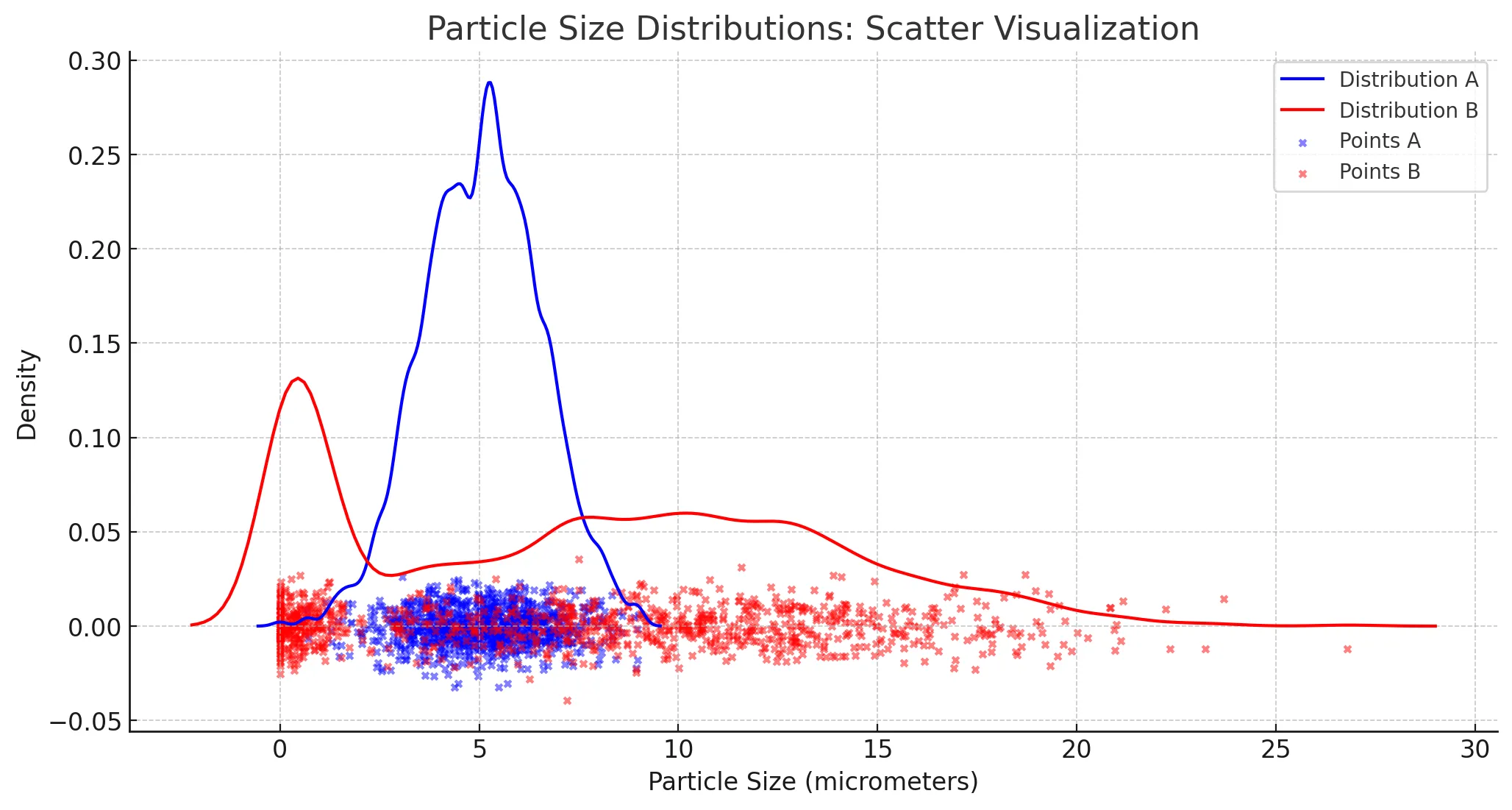

Sometimes glow-in-the-dark powders from different brands have the same particle size data but yield different luminescent effects, often due to the measuring methods and precision of particle size analyzers. These instruments calculate an average value by analyzing the particle size distribution of a sample, but this average might hide the actual variation in distribution. For instance, two data sets may have the same average particle size, but their distribution ranges and extremes could vary significantly, leading to markedly different effects in actual use. Therefore, reliance should not solely be on TDS (Technical Data Sheet) values but rather on the advice and solutions provided by professional teams and actual production testing of samples to compare the end product’s effect.

In summary

When selecting glow-in-the-dark powder, priority should be given to manufacturers or distributors with professional laboratories and advanced equipment, as they can provide relatively accurate product parameters and ensure stability. Secondly, data on the TDS should only be used as a reference. To ensure the best effect of the final product, it is advisable to get samples based on the supplier’s recommendation and conduct production tests to ensure the selected product meets specific requirements.

Glowup® boasts over 20 years of rich experience, having collaborated with various industries and well-known brands. Our customer projects span a variety of materials and production processes. We aim to offer the most professional advice, assisting customers in choosing the most suitable glow-in-the-dark powder, avoiding repeated trials during the development stage, and saving our clients time and effort.

Leave A Comment