In the glow in the dark powder industry, the recognized testing standard is <DIN 67510>. This standard, established by the German Institute for Standardization (Deutsches Institut für Normung, DIN), specifies that the testing conditions for glow in the dark powder should be in a completely dark laboratory environment, using a D65 light source with a luminous intensity of 1000 lux, and irradiating for 5 minutes. This standard is widely recognized and applied in Europe and internationally. However, even when all conditions strictly adhere to the <DIN 67510> standard, can we be certain that the test results are accurate? Not necessarily.

Through communication with our customers, we have found that although the luminosity values on our Technical Data Sheets (TDS) are not as high as those of our competitors, customers have reported that our products display higher brightness when viewing the samples themselves. Upon analysis, we realized that in addition to the requirements mentioned in <DIN 67510>, factors such as the accuracy of the measuring equipment, the distance of illumination, the measurement area, and even the ambient temperature can all influence the final test values. To provide customers with more professional and stable testing indicators, we have upgraded our testing conditions. Currently, Glowup’s glow in the dark powder is measured using the Konica LS-150 luminometer and strictly follows the <DIN 67510> standard. All tests are conducted in a completely dark, constant temperature, closed laboratory environment using fixed molds.

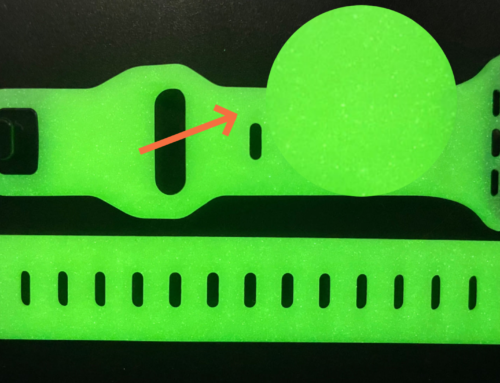

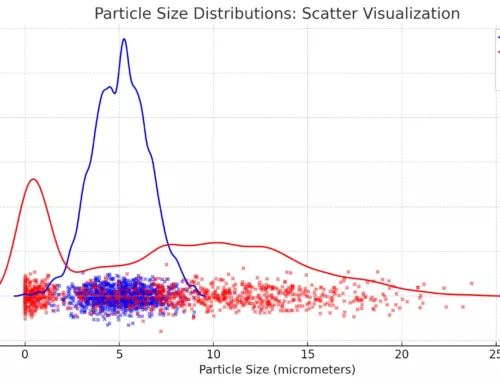

Furthermore, particle size is also an important factor affecting the brightness of glow in the dark powder. Generally, the larger the particle size, the more photons it can store, and the higher its brightness. Therefore, when comparing the brightness of different glow in the dark powders, ensuring that they have the same particle size is a very important prerequisite for a meaningful comparison.

Conclusion:

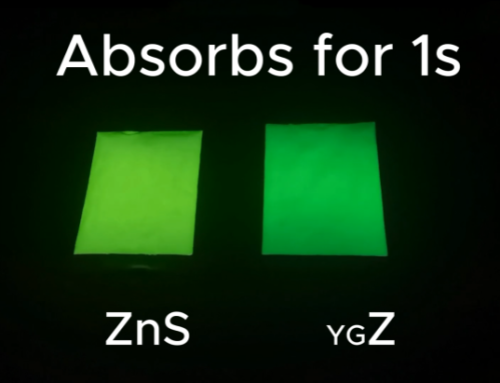

However, in practice, it is unlikely that all the testing conditions mentioned above from different suppliers can be completely consistent. Therefore, for customers with testing equipment, the most accurate method is to obtain different glow in the dark powder samples and conduct testing and comparison personally. For most customers without testing equipment, we recommend that when comparing the luminosity data in the TDS, first confirm the following three points: particle size, light intensity, and duration of illumination. With these conditions consistent, use the data as a reference, then obtain samples and personally compare observations to select the glow in the dark powder with the highest brightness.

Leave A Comment