防水夜光顏料

防水夜光顏料是透過在普通顏料顆粒上塗上一層外膜來實現的。目的是使夜光顏料能夠與水或水性介質(例如油漆、油墨和樹脂)接觸。

我們的防水技術已獲得日本專利。不僅在與水性介質混合時,而且在雨季的街道標誌和戶外設施上,或印在衣服、毯子等紡織品上,甚至在經過多次處理後,它在防水性能方面始終表現出出色的可行性和可靠性。水洗。即使浸入海水中,也能表現出穩定的耐水性。

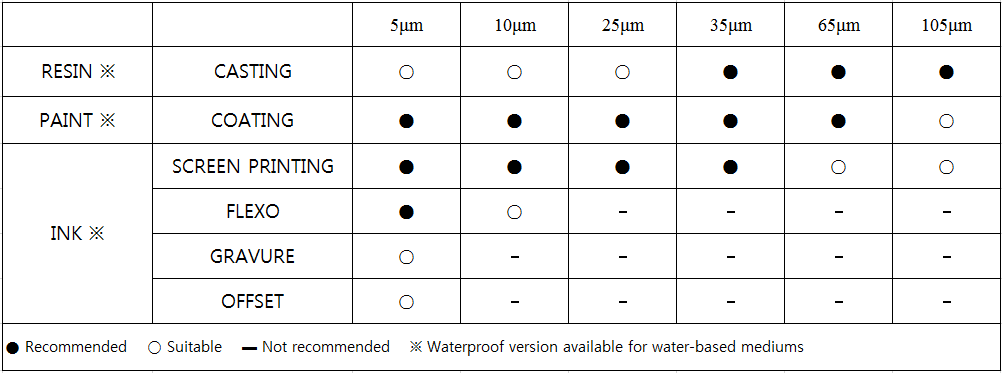

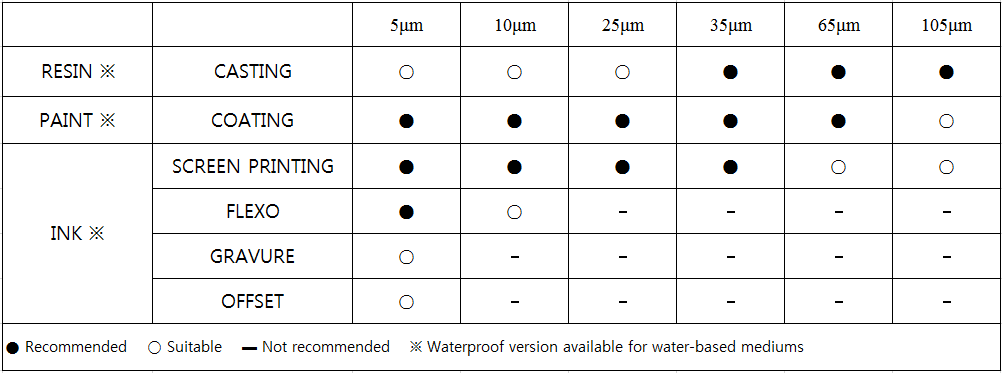

應用與推薦

防水夜光顏料是透過在普通顏料顆粒上塗上一層外膜來實現的。目的是使夜光顏料能夠與水或水性介質(例如油漆、油墨和樹脂)接觸。

我們的防水技術已獲得日本專利。不僅在與水性介質混合時,而且在雨季的街道標誌和戶外設施上,或印在衣服、毯子等紡織品上,甚至在經過多次處理後,它在防水性能方面始終表現出出色的可行性和可靠性。水洗。即使浸入海水中,也能表現出穩定的耐水性。