Glow in the dark powder can absorb and store light energy, then emitting a glow in the dark. Glow in the dark powder can be mixed into transparent, colorless neutral ink and applied to the surface of various materials through screen printing. Glow in the dark screen printing can be used on different types of textiles and crafts, such as clothing, home decor, and outdoor traffic products.

Using glow in the dark powder in screen printing not only adds a glowing effect to products and enhances nighttime visibility, but also brings more fun to consumers, increasing the aesthetic appeal and value of the products.

So, how do we choose and apply glow in the dark powder in screen printing?

1. Selecting glow in the dark powder

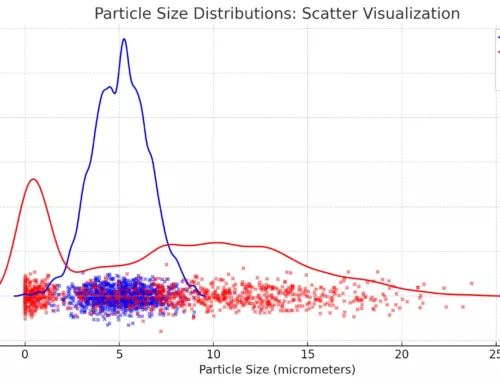

Choose the appropriate glow in the dark powder particle size based on the mesh count to ensure that the glow in the dark ink can pass through the screen entirely. You can consult experienced glow in the dark powder suppliers for specific recommendations.

2. Adjusting glow in the dark powder proportion

The dosage of glow in the dark powder has a significant impact on the glowing effect. Too low concentration will result in poor glow effect, while too high concentration will increase costs and affect print quality. You need to test based on your desired brightness and cost .

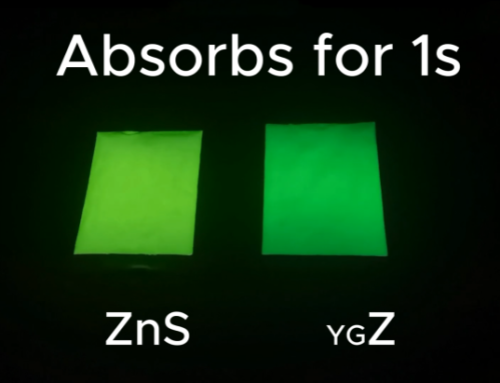

3. Glow in the dark powder colors

Glow in the dark powder comes in different colors, but different colors have varying brightness and afterglow. The natural colors of glow in the dark powder include yellow-green, blue-green, sky-blue, and natural-purple, with decreasing brightness in that order. Other colored glow in the dark powders are mixed by a certain proportion of colored fluorescent powder with natural glow in the dark powder, but the fluorescent powder will cover part of the brightness of the glow in the dark powder. Therefore, colored glow in the dark powders are typically used in products requiring colored appearance during the day, such as printing a glow in the dark logo on a T-shirt. Such applications do not require a long-lasting afterglow.

If there is excessive residue on the screen during printing, it is usually due to the glow in the dark powder particles being too large, the addition ratio being too high, or the ink viscosity being too high. The solutions are below:

a) Use a smaller particle size of powder.

b) Reduce the addition ratio.

c) Dilute the ink.

In conclusion, when you select and apply glow in the dark powder in screen printing ,you need to consider multiple factors and make adjustments and optimizations based on specific situation. As a glow in the dark solution expert, JOLIN has accumulated years of experience and numerous cases in glow in the dark screen printing. We will provide customers with glow in the dark solutions that meet their needs.

I think I would be very willing to pay for such beautiful luminous clothes.

Thank you for your affirmation. Glow in the dark powder can be mixed with any transparent neutral medium to complete any product you want.

The elements of Disney with luminous effects are really beautiful.

Can it also be used for fibres?

How do I get the sample? Please contact me