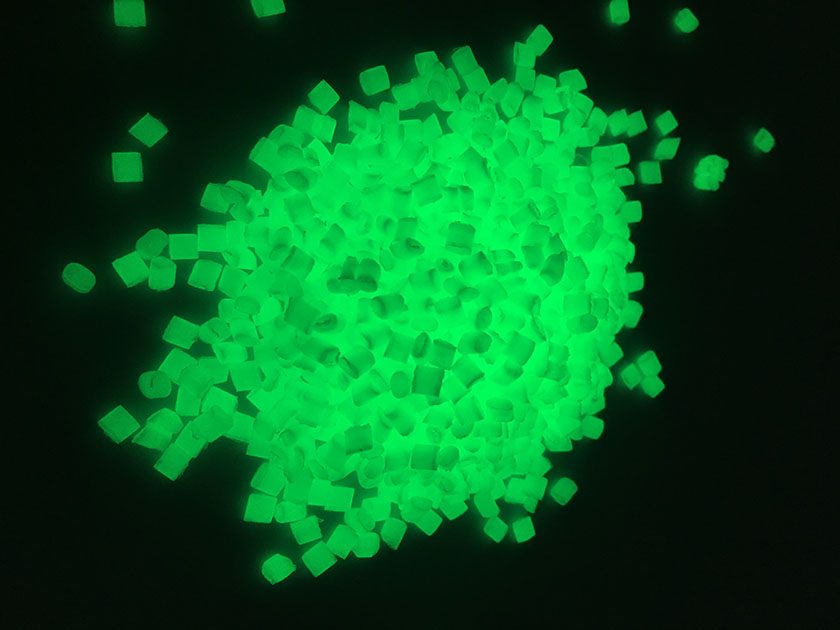

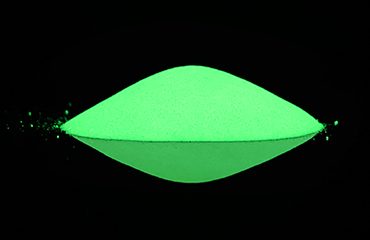

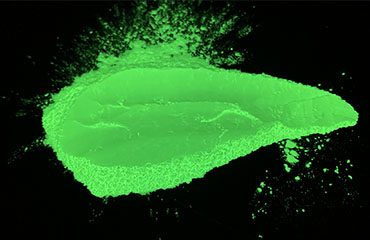

brilho no pó escuro misturado com plástico

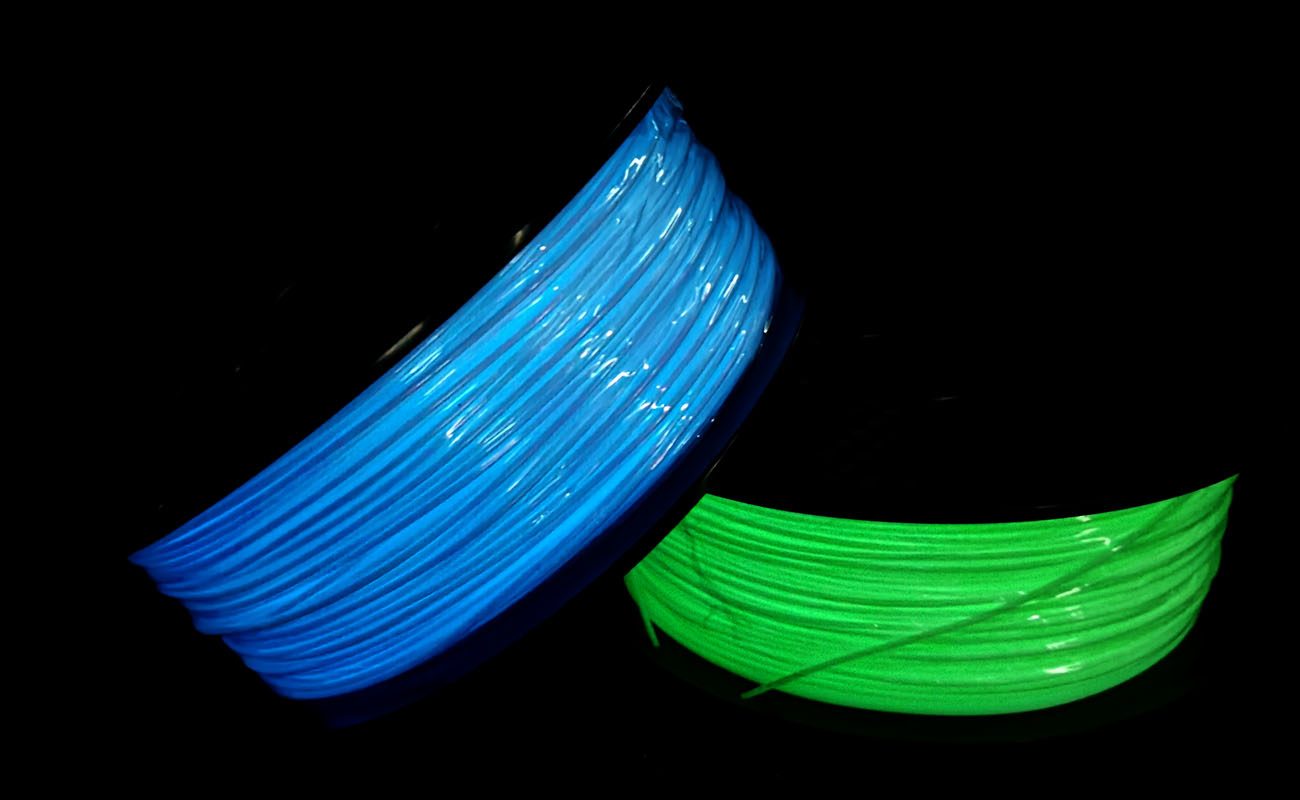

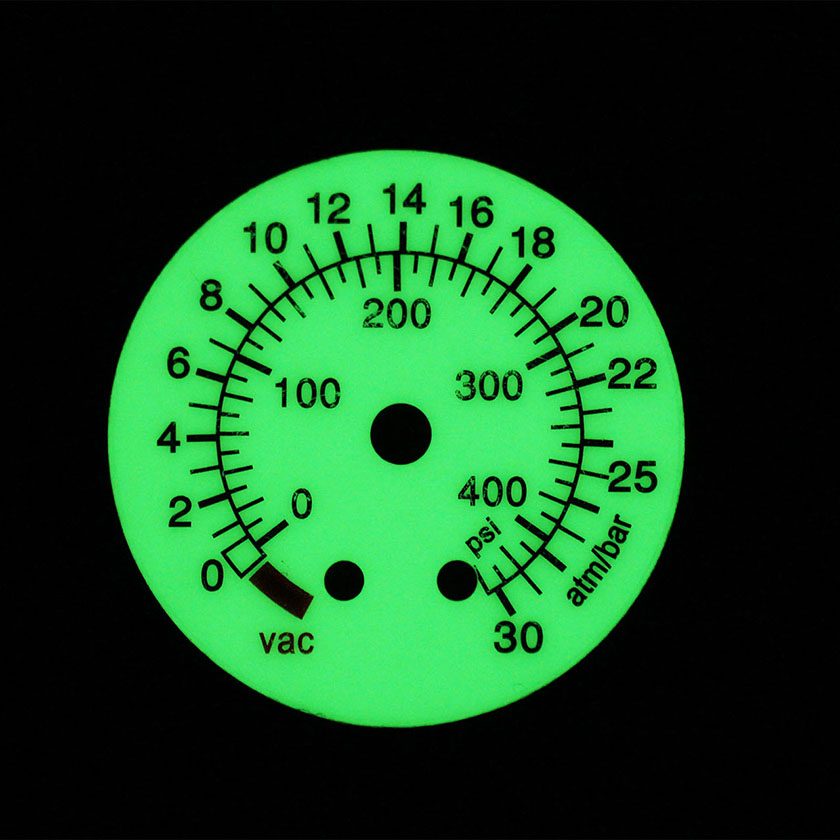

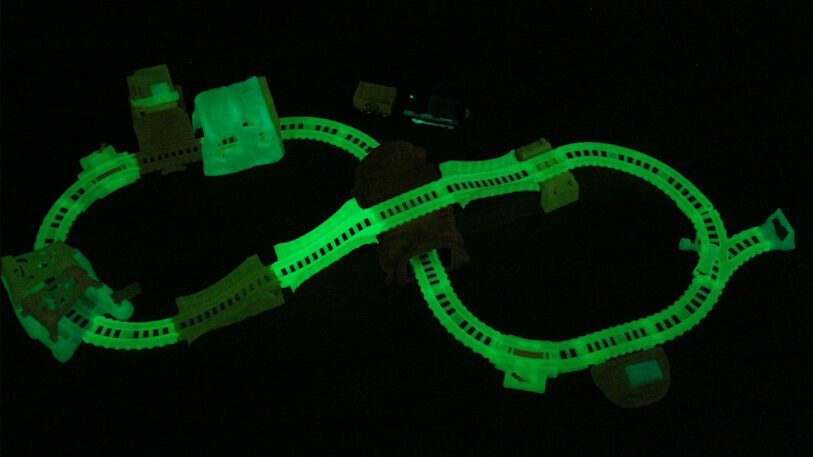

Glow in the dark powder can be mixed with various transparent and colorless plastics material, such as PP, PE, PET, PVC, ABS, PLA, PS, AS, Surlyn resin and so on to create a variety of luminous plastic products.For example, you can make various glowing parts or accessories,glowing plastic cups or container by injection molding equipment or you can make glowing master batches,glowing 3D cables by extrusion machines and more!

Nossa fábrica desenvolveu um pó especial que brilha no escuro para aplicação em materiais plásticos. Comparado com o brilho comum no pó escuro, não é fácil escurecer quando usado para moldagem por injeção ou extrusão, e seu nível de brilho é maior.

O pó que brilha no escuro vem em diferentes cores e tamanhos de partículas, você precisa escolher um de acordo com sua aplicação e requisitos de processo. O pó que brilha no escuro não é tóxico e é ecologicamente correto, sem qualquer radiação, então você não precisa se preocupar com radiação ou problemas de saúde durante o uso