Time: April,2023

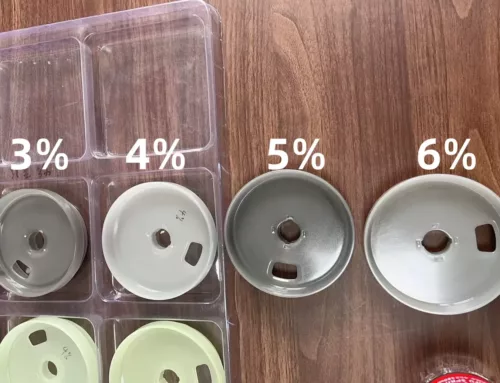

Cases: Use glowing powder named MG-B4-RW (Magenta glow, particle size 30-40 microns, waterproof grade night glow powder) to glow in the dark screen printing on the cup and enter the dishwasher for testing.

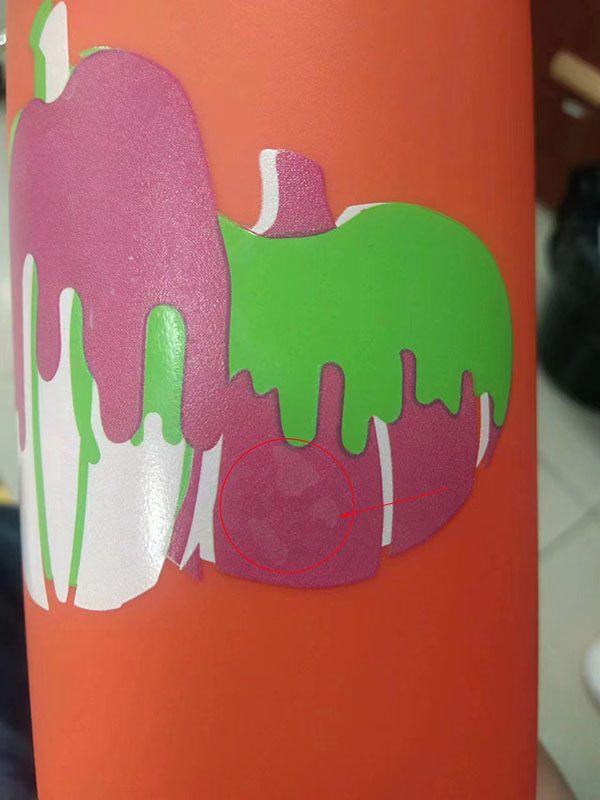

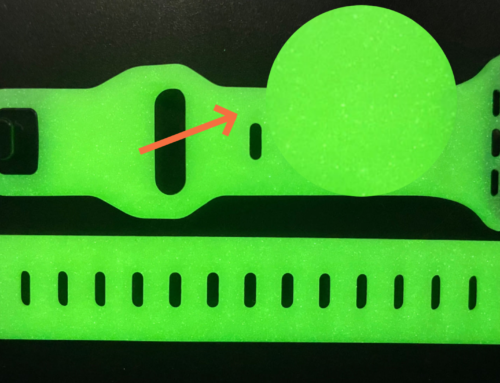

Problem Arising: After testing it in a dishwasher, the customer noticed a problem. In natural light, some patterns appeared blotchy and discolored, while the glow in the dark effect appeared rough and uneven.

Tested

Analysis & Solutions:

In this case, the customer produced glow in the dark screen printing cups using our magenta glowing powder, named MG-B4-RW.( The final product before dishwasher testing is as below)

Not Tested

After analysis, this was due to the strong impact force of the water flow on the surface of the object when the dishwasher is working, which damages the glow-in-the-dark layer. To solve this problem, we suggested to the customer to add a sufficiently thick layer of topcoat on the surface of the glow-in-the-dark layer, which can withstand the water flow impact of the dishwasher and avoid damage to the glow in the dark layer, ensuring the quality and durability of the product.

In this case, it is evident that producing glow-in-the-dark screen printing cups requires attention to detail to ensure product quality and durability. We hope that these recommendations will help customers solve issues and improve their understanding of glow-in-the-dark screen printing.

This article not only helps businesses but also customers like me. I didn’t realize that dishwashers could affect the glow in the dark layer on these cups. The recommendation to add a protective topcoat is practical and should help ensure the longevity of the glow effect. Thanks for sharing this knowledge!

I’m glad my article can help you because washing dishes can cause some friction, and the length of use can have a certain impact on the surface of the object.