Time: October 2023

Cases: The customer plans to mix glow in the dark powder with clear transparent silicone, add colorants for tinting, and create colored luminous remote control silicone covers.

Problem Arising: After the first batch of samples, the glow in the dark powder silicone product appears too dark in color, leaning towards solid colors, and the glow in the dark effect is not as bright as the competitor’s (other) product. The customer would like to know how to adjust it to achieve a higher brightness than the competition.

Other

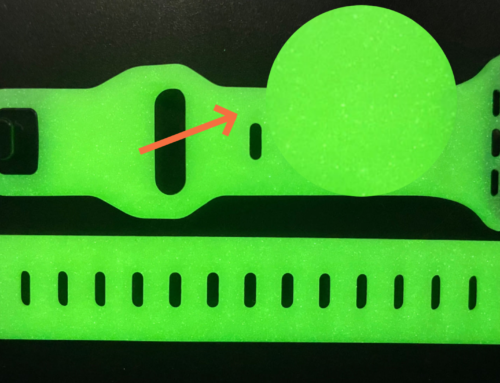

First batch of samples

Analysis & Solutions: After analysis, there are two reasons for the low brightness in the first batch of samples: the glow in the dark powder was added at a low ratio of only about 2%-2.5%, and the colorant ratio was too high. The product has a heavy body color, which also obscures the luminous effect.

We recommend increasing the ratio of glow in the dark powder, but the manufacturer has indicated that due to process limitations, this ratio is already at its maximum, and further increases may result in cracking. Therefore, adjustments need to be made in terms of color.

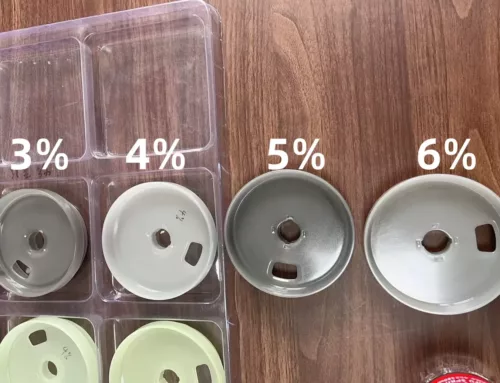

First, it’s essential to reduce the amount of colorant added to maintain a semi-transparent appearance of the final product, which allows the luminous effect to be preserved to the maximum extent.

Secondly, in the first batch of samples, three different colors were used simultaneously – yellow-green, teal, and sky blue. For the second round of sampling, we considered using only yellow-green Glow in the dark pigment as the base for tinting since yellow-green is the brightest among all luminous colors.

Second batch of samples

After implementing the above two improvement strategies, the manufacturer produced another set of samples, which received high praise from the customer.

This silicone product case demonstrates that to achieve the best colored luminous effect, in addition to adjusting the ratio of glow in the dark powder according to the customer’s requirements and the manufacturing process of the final product, it’s crucial to minimize the amount of colorant used. Excessive colorants can obscure the luminous effect, and maintaining a semi-transparent appearance is essential to preserving luminous brightness. If yellow-green luminescence is acceptable, it’s advisable to use yellow-green glow in the dark powder as the base for tinting.

What an amazing discovery, can I get some samples?