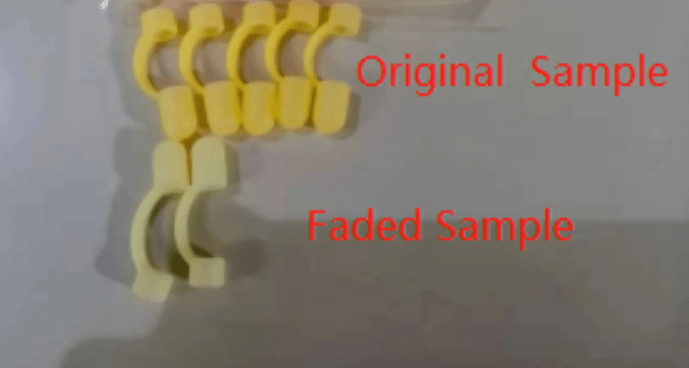

In the current market, most of colorful glow in the dark powder has the problem of body color fading when meeting temperature of 170-180℃ and above. As below picture shown, this is a silicone product whose body color faded due to high temperature vulcanization process.

Ordinary dyed luminous powder fading phenomenon

Our R&D team always focus on improving the performance of our products based on customer needs. After getting feedback from our customers, we immediately started a project to develop colorful luminous powder that can bear higher temperatures.

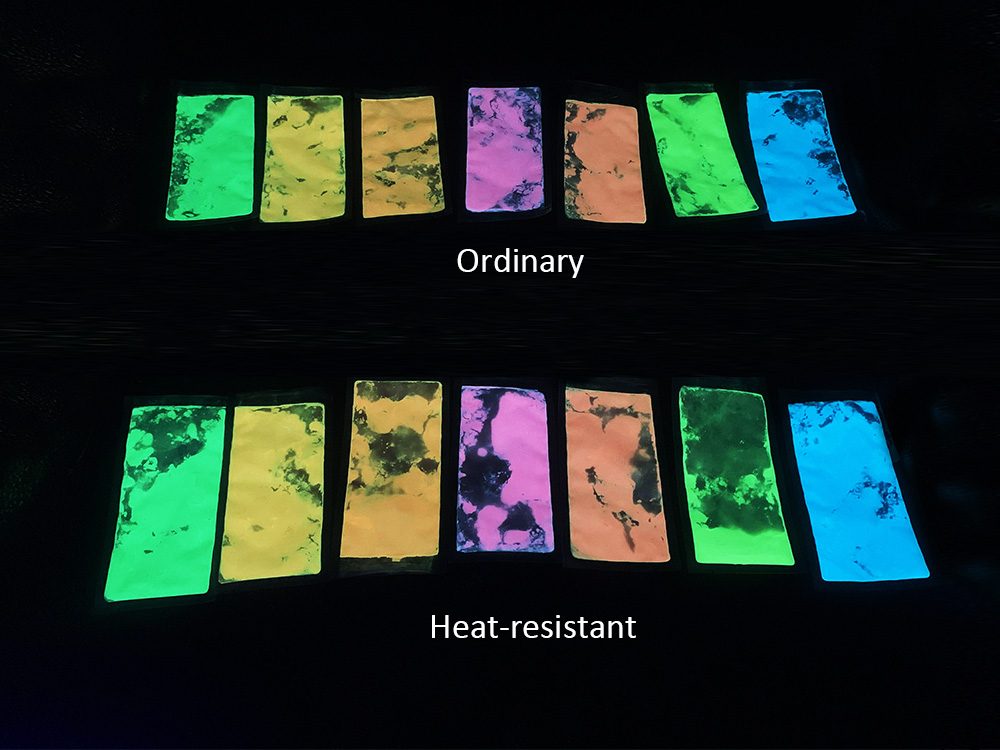

Heat-resistant colorful luminous powder (night)

Officially launched heat-resistant colorful luminous powder

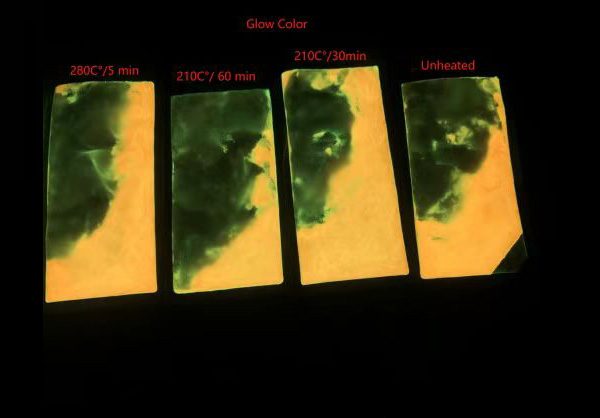

After continuous experiments and research, our heat-resistant colorful glow in the dark powder studied successfully. Below was an experiment of sample we did. After heating glow pigment for 30~ 60 minutes under 210C° and 5 minutes under 280C°,both the body color and glow color can retained as those of unheated sample! We have officially launched our heat-resistant colorful glow in the dark powder, and hope it will meet more market demands in the future!

Excellent luminous effect.

Thank you for your recognition. We will continue to move forward on the path of developing new products.

Amazing discovery.

Great share!

Beautiful colors